Product description

Safety

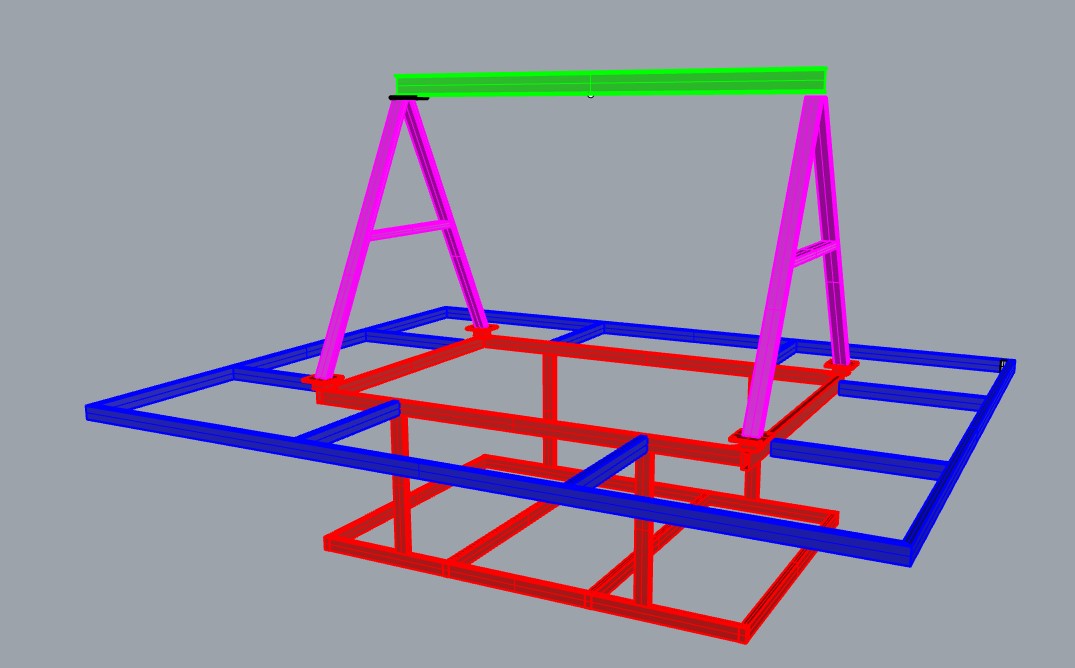

The centre of the structural steel frame of the pump pontoons have a low-slung chassis (gull wing design as shown below) to ensure the pump base sits below the deck of the pontoon. This lowers the centre of gravity for increased stability and also prevents the pump sliding on the pontoon which otherwise may cause load imbalance, tipping or roll over.

SPECIFICATION

- floating submersible pump station are designed to set the pump on the floating, apply to lakes, reservoirs, tailing and other due to large differences in water level, uncertain frequency fluctuation and fixed pump station have been unable to meet the requirements for life and industrial.

- Simple structure with Convenient transportation, ease to installation

- Higher of pump efficiency, low costs

- We are designed to accommodate submersible and vertical turbine pumps of all sizes in additional to safe and easy access for operators. The size of the center gap can be customized by changing the dimension of the grating connection assembly.